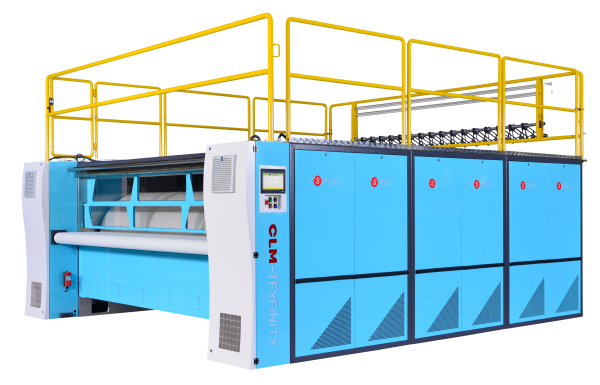

Steam Heat Chest Ironer

| Dimension | R 1200 x 3000. 3300. 3500. 4000 |

|---|---|

| Roll Dia | 1R. 2R. 3R. 4R |

| Heat Type | Steam Heat Type. |

| Characteristic | |

| Characteristic | |

| Characteristic | |

| Characteristic |

목록으로

- PREVIOUSSheet folder with S-Tacker

- NEXTGas Heat Chest Ironer

본문

1. Speed [High Ironing Speed]

Thanks to advanced engineering and the use of intelligent technology, the SI-iron is a top performing machine, tuned for high production laundries.

• Up to 60 m/min

• Direct drive technology to control the speed of the rolls

• Speed difference between the rolls are programmable per type of linen

• 11kW motor for each roll to reach a high speed without pushing the motors to their limit

• Positioning of the rolls is used for assuring a very precise speed regulation

• The high efficiency of the SI-iron leads to a higher speed for the same capacity of drying

2. Quality [Advanced Technology and Ironing Perfection]

Our continuous efforts in maximising the reliability of the SI-iron has led to a robust, industrial design with top quality parts. This results in a very high ironing quality and extends the lifetime of the ironer.

• The flexible chests are designed, developed and built by CLMTexfinity

• The chests are made of stainless steel (both sides)

• Unique and patented optimised oil flow without any cold spots and an extremely low pressure drop

• Each motor controlled via individual frequency inverter

• Planetary gearboxes for a long life and high efficiency, lower noise, smoother operation and higher torque

• Top brand parts: pneumatics, electronics, modulated burner, rolls, motors and drivers

• High capacity 3-pass heat exchanger

• Robust construction

• Top level isolation improving the efficiency

• State of the art safety systems monitoring the correct operation of each function

• Large diameter oil circuit pipes assure a high flow rate at relative low speeds, reducing flow losses and avoiding temperature drops in the chests

• High power axial oil pump, running at medium speed for a long life at high flow rates

3. KiSS [Keep it Simple & Straightforward]

Keeping it simple, the design of the SI-iron and its user interface makes it easy to understand, easy to use and easy to maintain. Using standard parts, widely available surely helps.

• Minimum moving parts, no belts or chains (independent and direct drive)

• Thanks to an ingenious design, oil contamination is reduced to a minimum level, boosting the lifetime of the oil in the ironer

• 100 recipes

• 10-inch color responsive touch screen of high resolution and straightforward menu structure makes generating and changing programs effortless

• One button operation for starting and stopping an integrated line

• Integration with feeder and folder

• Easy maintenance!

• Standard parts widely available

4. IoT [Internet of Things]

Taking full advantage of the interconnectivity, the SI-iron machines became cyber-physical solutions, continuously streaming data, leading to more automation, higher efficiency, machine learning and real-time information.

• Selection of the recipe linked with feeder/folder or indirectly to other external systems

• Storage of production data

• Connection with central database

• Integration with smart conveyors already prepared in the machine

• Operation/service/productivity via smartphone or tablet

5. Smart [Iron Smart!]

Making the SI-iron more and more intelligent lowers the need for complex adjustments and corrects human errors. Smart machines interconnect, optimise the use of ressources and generate the information you need, when you need it.

• Even at high speed, the oil maintains a constant temperature thanks to the modulated burner and highly intelligent auto-correction system

• The intelligent speed recall system, related to article and customer, assures the ironer always runs at the optimum speed for the specific type of linen and moisture retention

• Automatic speed adjustment based on humidity of the linen at the exit

• Central automatic speed control

• Central recipe selection - recipes of machines are linkable to each other

• Powerful air extraction adjustable per roll and speed depending to optimise the water evaporation per roll to reach the highest speeds

• Customer and article selection will select the optimum recipe for the line

6. Flex [The Art of Flexibility]

Continuously listening and learning from our customers made the SI-iron a highly flexible ironing machine, adaptable to specific needs, easy to customise and integrate into existing installations.

• Several versions are possible 1, 2, 3 rolls, working width etc.

• With or without feeding belts

• Ironing all type of sheets, duvet covers, pillowcases, table linen, napkins etc.

• The SI-iron can be connected with every type (from every brand) of feeder and folder

• Optional trailing edge guidance for wrinkle free ironing

• Optional moving guiding tape system avoids tape prints on the felts

• Integration with CLMTexfinity feeders and folders, and optional integration with other brands

• The Display can be put on the left or on the right hand side of the ironer

7. Eco [Nature-Friendly]

A well-thought design lowers the need of energy and air, leading to savings for our customers and reduces the ecological footprint.

• Thanks to the intelligent design, a well-thought chest and optimised oil distribution system, the SI-iron has a maximum output with a minimum of ressources

• Top level isolation

• Intelligent speed control avoids running the ironer at too high speeds, optimising the gaps between the sheets which reduces the losses

댓글목록

등록된 댓글이 없습니다.